Other Equipment

We provide a range of improvements and features designed to be implemented on existing machines, allowing you to benefit from the added value of upgraded assets. These solutions are meant to be compatible with existing technology from any machine manufacturer. Our offer includes, but is not limited to, Side Panels Equipment, Textile Backsheet in-line and Single Wrap unit.

ADULT DIAPER AND BABY DIAPER SIDE PANELS EQUIPMENT

ADULT DIAPER AND BABY DIAPER SIDE PANELS EQUIPMENT

Complete equipment for baby and adult diapers back and front ears, symmetric and asymmetric with 0-trim and low trim.

ELECTRONIC TURN & REPITCH

ELECTRONIC TURN & REPITCH

The electronic turn&repitch is a CCS patented process solution that allows for seamless insert rotation and application on chassis at high speed with high precision.

The new turn&repitch is electronically actioned by servo motors and all size change operations can be reduced to a minimum through mostly acting on software settings and minor mechanical adjustments. The result is increased efficiency and reduced downtime.

SINGLE WRAP UNIT

SINGLE WRAP UNIT

Complete equipment for the individual wrapping of baby diapers

· off line polyethylene unwinding unit · full servo driven transmission

· speed up to 1.200 pieces/min

FOAM APPLICATOR

FOAM APPLICATOR

CCS developed an innovative process to cut and apply the FOAM material on Light Incontinence products improving the softness and comfort of the product. The CCS FOAM applicator represents the most competitive solution in the market successfully tested at 1500 PPM.

EASY WRAP UNIT

EASY WRAP UNIT

Complete equipment for the individual wrapping of sanitary napkins and panty liners

· turning unit

· with or without peel strip

· with or without closure tape

· threefolded products

· speed up to 2.000 pieces/min.

CORE CHANNELS

CORE CHANNELS

CCS introduces an innovative process design for products with “Core Channels”, the most advanced and competitive technology for the manufacturing of premium disposable hygienic products for baby open diapers, baby pants, adult diapers and adult pants.

The “core channels” enhance product performances strenghtening core integrity, improving liquid distribution and drastically reducing acquisition time and rewet. Moreover, the channels definitively improve the fitness of the product

INTERMITTENT SAP PROCESS

INTERMITTENT SAP PROCESS

The intermittent SAP process allows you to concentrate the SAP in the most effective area of the absorbent core. Compared to a continuous SAP process, the intermittent will offer you the opportunity to reduce the total amount of SAP needed.

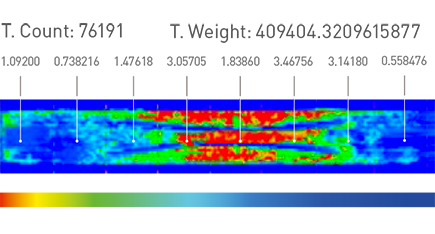

DRUM FORMING UNIT

DRUM FORMING UNIT

Complete drum forming with different fluff inlet and adjustable vacuum chambers - forming wheels with 3D or 2D cavities - discrete pads or continuous fluff mat with and without channels full servo driven.